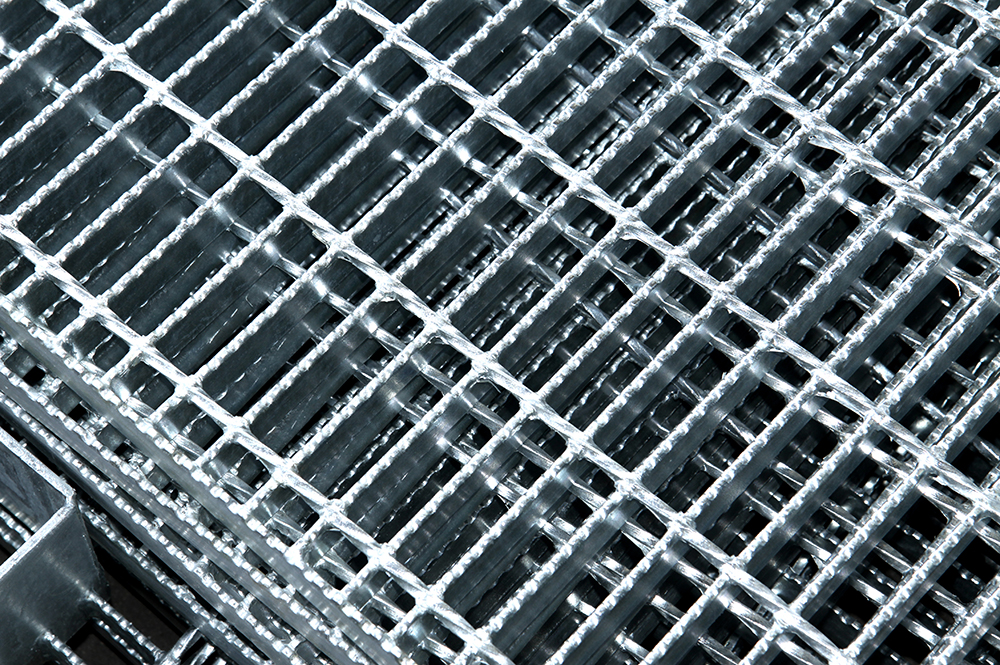

HOT GALVANIZING

The equipment of German companies Pilling, SCHEFFER and Stoeckl, Austrian companies KOERNER and SCHEUCH and Norwegian company C.H.Evensen has been installed at the hot galvanizing shop of the enterprise, with annual production capacity of 20 000 tons. In shop metalwares with dimensions of 14.5x1.4x2.7 can be galvanized automatically. At the same time, it is possible to galvanize constructions with dimensions up to 18 m in manual mode.

The initial processing of metal combines 9 (nine) units of technological baths locating in compacted area, 3 (three) spreader-bars, the dryer performing simultaneously and a scrubber designed to catch the air containing HCl (chloride acid vapor) in the area where the baths are located.

The quality control of zinc coating is carried out by test methods as per GOST 9.307-89. The metallic composition of the zinc bath is analyzed using a stationary BELEC LAB 3000s spectrometer. Galvanized materials have a service life of up to 75-100 years. They are widely used in areas requiring reliability and durability.

Flux layer acts as the catalyst in the galvanizing process. This layer also prevents oxidizations that may occur in drying chambers and during transport of spreader-bars to the zinc bath. The drying process is carried out through heater and under heating conditions up to 110-120 °C.

The hot galvanizing process involves entering metal structures into a molten zinc bath (~450-452 °C). Galvanized materials comply with the requirements of the EN ISO 1461: 2009 and ASTM A123 standards. High-quality (99.995 %) zinc is used to ensure high quality work in the galvanizing process.