General information

It was decided in 2013 to start fabrication of STP PVC door-window profiles and pipes by taking into account the needs of local market. In the beginning of 2014 Plant of Polymeric Products (PPP) firstly marketed its high quality new product – PVC door-window systems.

It was decided in 2013 to start fabrication of STP PVC door-window profiles and pipes by taking into account the needs of local market. In the beginning of 2014 Plant of Polymeric Products (PPP) firstly marketed its high quality new product – PVC door-window systems.

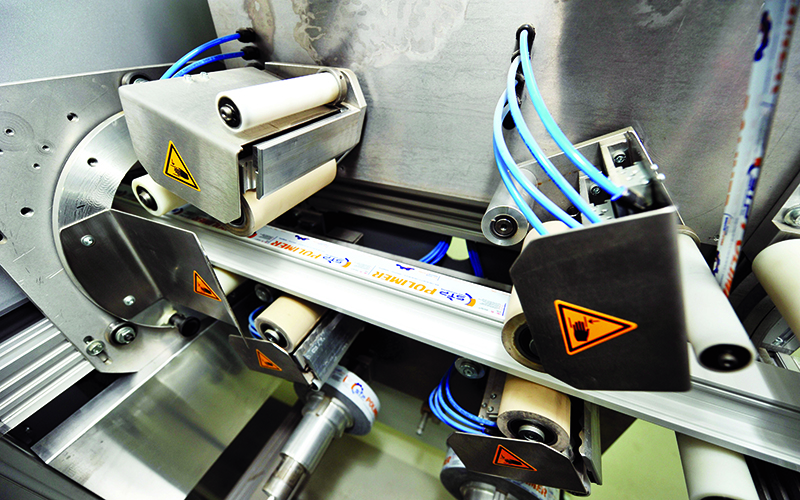

High-tech fully automated mixing and dosing technology was established in Plant of Polymeric Products with the help of Zeppelin Systems GmbH, Germany. Through this system raw material is automatically loaded in bins (silo) and finished raw mixture is transported to the extrusion line. Powerful aspiration system has been installed in this site which prevents the spread of dust to the environment during periodical process ensuring the area is kept clean.

Our profiles are produced in the most modern extrusion lines of Krauss Maffei Teсhnologies GmbH and in moulds and calibration equipment incorporating the latest technical achievements of Greiner Extrusion GmbH which provide ideal smoothness of the product surface. These companies are leaders in their regions.

of released profiles is provided by original recipe mixture prepared by IKA Innovative Kunststoffaufbereitung GmbH & Co. KG, Germany.

In order to achieve high quality production we use PVC resin of German company INEOS Vinyls Sales GmbH and chemical additives of world manufacturers such as DuPont International Operations Sarl, IKA Innovative Kunststoffaufbereitung GmbH & Co. KG, Kaneka, Erciyes. All of these allow us to get products with high quality physical-chemical properties and special whiteness.

In particular, we would like to mention that S60 and S70 PVC profiles produced by STP meet the standards of European Commission on environmental protection because during production the lead contained in stabilizer is replaced with environmentally safe calcium-zinc compound.

So, profile demonstrates several advantages, for example, environmentally safe calcium-zinc stabilizer provides long term whiteness and brightness of the face surface of PVC profiles in any weather condition.

Our profile system meets the quality requirements for Europe window profiles and GOST 30673-99 standard A class.

In modern times windows made of PVC profiles are optimum options for construction and reconstruction of the buildings. PVC profiles have high operation quality. They have several important advantages compared to the windows made of wood and aluminium and their price is cheaper.

Advantages of the modern PVC door and window systems:

1. Long term resistance to all weather conditions

PVC windows are durable and withstand all types of weather conditions. The snow, rain, sharp change in temperature do not effect on them. Life cycle of windows made of quality profiles is more than 40 years.

2. Aesthetic external appearance

Aesthetic external appearance of PVC windows will be suited to the interior of your office and house. The modern technologies allow us to produce windows in each size, forma and colour. Plastic windows may be produced according to each design and style.

3. Sealing (tightness)

Tightness of connections and usage of insulating glass units result in very high sound and heat insulation provided by windows. Installation of doors and windows made of PVC profiles will reduce your expenses spent for heating of your houses. The high sound insulation is actual for each person living in noisy cities.

4. Simple usage

Plastic windows do not require special care. They may be washed with simple detergents not containing solvent. There is no need for regularly usage of protective means. It is not required to re-paint and varnish and to further heat the plastic windows in winter months. Also, their all mechanisms and accessories do not require additional maintenance.

5. Fire safety

PVC is a hardly inflammable and self-extinguishing substance. Plastic windows meet both local and international fire safety standards.

6. Being environmentally friendly and absolutely harmless for human beings

Plastic windows do not release any harmful substances. Special certificates and different lab tests confirm that PVC is environmentally friendly and absolutely harmless for human health.

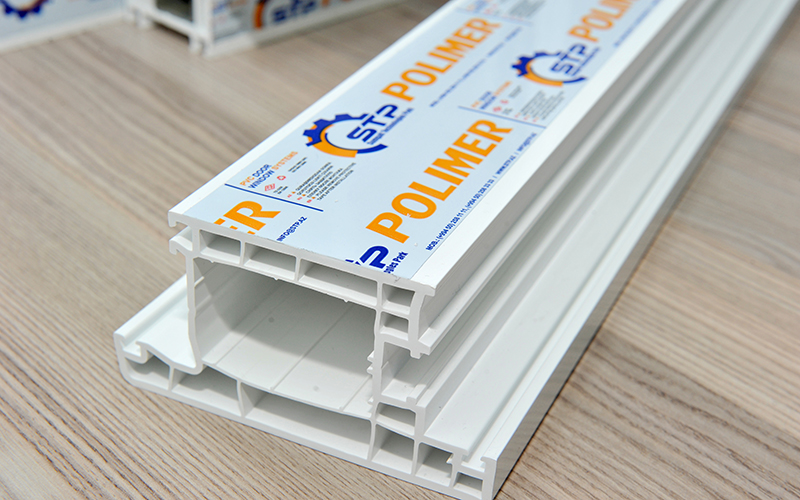

PVC S 60

- Profile system with mounting width of 60 mm

- Main profiles with structure of four chambers

- External and internal sealing system

- Thickness of external walls - 2,5mm.

- Single, double and triple insulating glass unit with thickness of 4mm-30mm

- Inward and outward opening door profiles

- enhanced light-conducting surface (face) has been achieved due to the minimized height of double profiles (frame+wing = 116mm).

- Individual reinforcing metal is applied in frame and wing profiles

- The axial distance of fitting hole of locked door and wing profile is 13 mm

- Maximum size of window wing - 150smx150sm

- Maximum size of door wing for balcony -90smx235sm

- Durability (conventional years) – more than 40 years

- Standard colour of sealant - black

- Frost resistance – up to minus 50C

- Resistance coefficient of heat conductivity, m2 0C/Vt - 0,70

- Reliable sound insulation up to 4th grade (43 dB)

- Possibility of installation of ventilation system (Regel-Air)

- PVC windows of PVC S 6000 system c/w appropriate fitting guarantee resistance to break

- Suitable in various colour spectra

- Waterproofness- class A, at least 600 Pa (GOST 30673-99)

- Air permeability - class A, 3 m3/m2 •s (GOST 30673-99)

- Wind resistance - class B, 800-999 Pa (GOST 30673-99)

PVC S 70

- Profile system with mounting width of 70mm

- Main profiles with structure of six chambers

- Internal and external sealing system

- Thickness of external walls - 2,5mm

- Single, double and triple insulating glass unit with thickness of 4mm-30mm

- Inward and outward opening door profiles

- •Enhance light-conducting surface (face) has been achieved due to the minimized height of double profiles (frame+wing = 116mm)

- Universal reinforcing metal is applied in frame and wing profiles

- The axial distance of fitting hole of locked door and wing profile is 13 mm

- Maximum size of window wing - 150smx150sm

- Maximum size of door wing for balcony-90smx235sm

- Durability (conventional years) – more than 40 years

- Standard colour of sealant - black

- Frost resistance – up to minus 50C

- Resistance coefficient of heat conductivity, m2 0C/Vt - 0,70

- Reliable sound insulation up to 4th grade (45 dB)

- Possibility of installation of ventilation system (Regel-Air)

- PVC windows of PVC S 7000 system c/w appropriate fitting guarantee resistance to break

- Suitable in various colour spectra

- Waterproofness - class A, at least 600 Pa (GOST 30673-99)

- Air permeability - class A, 3m3/m2s (GOST 30673-99)

- Wind resistance - class B, 800-999 Pa (GOST 30673-99)

Testing PVC profiles

All lab tests allow us to provide our customers with high quality products.

There is quality control laboratory in the Plant of Polymeric Products of STP. This laboratory has all types of equipment required for checking if profiles meet the requirements of GOST.

Requirement on PVC profiles are regulated by GOST 30673-99 and these profiles fully meet the requirements of GOST and approved by results of lab tests conducted.

Several tests conducted in our laboratory are described below:

1. Checking the colour and brightness

The colour and brightness of profiles are verified through high resolution equipment. The colour indicators are compared with benchmark indicators and when there is a minimum difference from benchmark the extrusion indicators are revised.

2. Checking the durability of welds of profiles

High quality STP polymeric profiles allow them to provide worthy durability of the welds. Durability of the welds is two times higher than standards.

This indicator is very important for door-window manufacturers. The high durability of the welds prevents the damages that may occur during tightening of the finished doors and windows.

3. Checking the impact resistance

The steel hammer of 1kg is lowered from 1.5 m height onto profile sample cooled to 20°C in advance. The test is conducted on 10 samples and absence of hardly visible damages and cracks on profile surface confirms that the sample has successfully passed the test. In the event that 9 out of 10 samples have successfully passed this test the positive feedback is given to the profiles. STP polymeric profiles successfully pass this test.

4. Checking the heat resistance

Firstly, the profile sample is heated up to +150°C in the heating cabinet, then is cooled to the room temperature. After this, visual inspection is conducted on the sample to check if there are any damages.

Absence of any damages on STP PVC profiles during heat resistance inspection proves that the extrusion has been correctly done and there are not layered gaps inside profile.

Not finding these negative cases in the profile samples indicates that there will not be any difficulties during welding in future.

5. Checking the profile geometry parameters

In accordance with the requirements of GOST 30673-99 more than 20 parameters should be continually kept under control during profile production. In practice our specialists always verify the thickness and spacing of all walls.