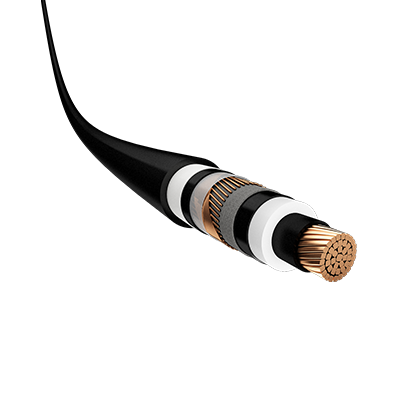

N2XSY-LS (cat A)

General information

Standard: AZS 418-2010 (TS İEC 60502-2), TSE K 204 The Russian analogue: PvVng (A) -LS The cable is used for fixed installation in cable lines and the industrial areas. The cables can be laid on dry ground, and have no restrictions on the level difference either. The cable does not spread combustion in case of group cabling.

Single-core high voltage cable with a copper conductor, with cross-linked polyethylene (XLPE) insulation, and flame retardant polyvinyl chloride sheath with low smoke and gas emission

Structure:

- The conductor is copper, multi-wire compacted, round form, corresponds to class 2 of IEC 60228

- The cross-section of a multi-wire compacted round conductor is 25÷800 mm2

- The cross-section of a multi-wire compacted round conductor, consisting of 5 sectors, is 1000÷1600 mm2

- The outer conductor screen is made of extruded semiconducting cross-linked polyethylene

3. Insulation is cross-linked polyethylene (2X)

4. Insulation screen is made of extruded semiconducting cross-linked polyethylene

5. The separation layer is made of electrically conductive water-blocking tape

6. The screen of copper wires fastened with copper tape (S)

Minimum cross-section of screen for cables with a conductor cross-section of 25-120 mm2 is 16 mm2

Minimum cross-section of screen for cables with a conductor cross-section of 150-300 mm2 is 25 mm2

Minimum cross-section of screen for cables with a conductor cross-section of 400-1000 mm2 is 35 mm2

Minimum cross- section of screen for cables with a conductor section of 1200 mm2 and above is 50 mm2

The maximum cross-section of screen can be set based on the customer's request.

- Thermal barrier is made of glass or mica-containing tape, corresponds to category A according to IEC 60332

8. Inner sheath is made of flame retardant polyvinyl chloride with low smoke and gas emission

9. Thermal barrier is made of a glass or mica-containing tape, corresponds to category A according to IEC 60332

10. External protective sheath is made of flame retardant polyvinyl chloride with low smoke and gas emission (Y-LS)

Specifications:

- Operating conductor temperature: +90 0C

- The maximum temperature of heating the cable conductors in case of emergency: +130 0C

- The maximum temperature of heating the cable conductors in case of a short circuit: +250 0С

- The duration of a short circuit (not more than): 5 seconds.

- Cable laying temperature (not less than): -15 0С

- Ambient temperature: -50 / +50 0C

- Minimum bending radius of the cable: 15xD (D – outer diameter of the cable)

NOTE: Technical specifications are given in Table 1