ОКГ

General information

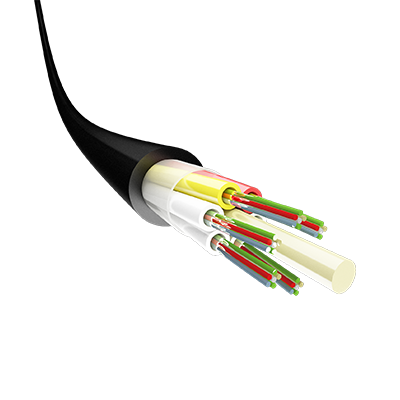

U-DF2Y (ОКГ) type fiber optic cable with a central tube on which aramid yarns or glass yarns are put, single-layer-coated for cable jetting

STRUCTURAL DESIGN OF CABLE

Optical fibers are freely placed inside polymer tubes and interstice is filled with a hydrophobic gel. Polymer tubes are SZ stranded around a central-strength member. Interstice between stranded tubes is filled with hydrophobic gel and covered with PET tape. Next, the core is sheathed with a high-dense polyethylene sheath (cables with high fire safety level are sheathed with LSZH compound).

- Central member

- Hydrophobic gel

- Optical fiber

- PBT tube

- PET tape

- Outer protective jacket

COLOR IDENTIFICATION OF FIBERS AND TUBES (IEC 60304)

1-12 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

Fiber | red | green | dark blue | yellow | white | grey | brown | purple | blue | black | orange | pink |

Tube | red | green | dark blue | yellow | white | grey | brown | purple | blue | black | orange | pink |

On customer’s request, the color identification of fibers and tubes (and color assembly sequence of tubes) can be changed.

Number of fibers | 26-48 | 50-72 | 74-96 | 98-144 | |

Number of tubes (max) | 6 | 6 | 6 | 8 | 12 |

Number of fibers in a tube (max) | 4 | 8 | 12 | 12 | 12 |

Temperature range during operation | -40 °C.....+60 ºC |

Temperature range during installation | -10 °C.....+50 ºC |

Temperature range during transportation and storage | -50 ºC......+50 ºC |

Minimum bending radius | 20xD |

Tensile strength (IEC 60794-1-2) | 1 ÷ 3.5 kN |

Crush strength (IEC 60794-1-2) | 3.0 kN/100 mm (min) |

| Temperature range of operation | -40°C.....+60ºC |

| Temperature range of installation | -10°C.....+50ºC |

| Temperature range of transportation and storage | -50ºC......+50ºC |

| Minimum bending radius | 20xD |

| Tensile strength (IEC 60794-1-2) | 1 ÷ 3.5 kN |

| Crush strength (IEC 60794-1-2) | 3.0 kN/100 mm (min) |