ОКЛТ

General information

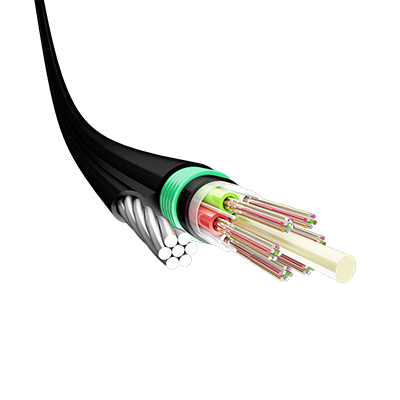

A-DF(ZN)2Y(SR)T2Y / A-DF(BN)2Y(SR)T2Y (ОКЛТ) type fiber optic cable armored with laminated corrugated steel tape, double-sheathed, with (eight-stranded) suspension rope for suspension on power line pylons

Structural design of cable

The bearing member is placed in parallel to the twisted conductor. The bearing member can consist of a steel rope or a dielectric-based strength member (fiberglass rod). Optical fibers are freely placed inside the tube and interstice is filled with a hydrophobic gel. Polymer tubes are SZ stranded around a central-strength member. Interstice between stranded tubes is filled with hydrophobic gel and covered with PET tape. Next, in addition to aramid yarns or fiber glass yarns, polyethylene inner jacket is imposed on the cable core. Internally jacketed cable core is sheathed with laminated corrugated steel tape armor, and the bearing member is sheathed with high-density polyethylene outer jacket.

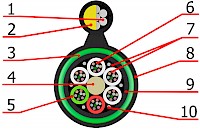

- Steel rope (T)/ steel wire (Ts)

- Glass rod (Td)

- Corrugated steel tape armor

- Central member

- PBT tube

- Optical fiber

- Gel

- Outer jacket

- Inner jacket

- Aramid yarns (ZN) or fiberglass yarns (BN)

Color Identification of fibers and tubes (IEC 60304)

1-12 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

Fiber | red | green | dark blue | yellow | white | grey | brown | purple | blue | black | orange | pink |

Tube | red | green | dark blue | yellow | white | grey | brown | purple | blue | black | orange | pink |

On customer’s request, the color identification of fibers and tubes can be changed.

Number of fibers | 2-24 | 26-48 | 50-72 | 74-96 | 98-144 |

Number of tubes (max) | 6 | 6 | 6 | 8 | 12 |

Number of fibers in a tube (max) | 4 | 8 | 12 | 12 | 12 |

Temperature range during operation | -40 °C.....+60 ºC |

Temperature range during installation | -10 °C.....+50 ºC |

Temperature range during transportation and storage | -50 ºC......+50 ºC |

Minimum bending radius | 20xD |

Tensile strength (IEC 60794-1-2 E1) | 1 ÷ 3.5 kN |

Crush strength (IEC 60794-1-2 E3) | 3.0 kN/100 mm (minimum) |

| Temperature range of operation | -40°C.....+60ºC |

| Temperature range of installation | -10°C.....+50ºC |

| Temperature range of transportation and storage | -50ºC......+50ºC |

| Minimum bending radius | 20xD |

| Tensile strength (IEC 60794-1-2 E1) | 1 ÷ 3.5 kN |

| Crush strength (IEC 60794-1-2 E3) | 3.0 kN/100 mm (not less than) |