A-DF(ZN)2Y(SR)2Y

General information

A-DF(ZN)2Y(SR)2Y/A-DF(BN)2Y(SR)2Y(OKL) type fiber optic cables with double sheath and armor made of corrugated laminated steel tape for laying in cable channels

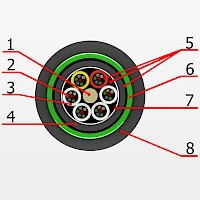

STRUCTURAL DESIGN OF CABLE

Tubes: the optical fibers are freely laid inside, and the free space is filled with a hydrophobic gel. Tubes are twisted around the central force element by the SZ-twist method. The free space between the twisted tubes is filled with gel and wrapped in a polyfilm. Then the inner sheath of polyethylene is imposed on the conductor, together with aramid or glass threads. An armor made of steel corrugated laminated tape and an outer shell made of high density polyethylene are placed on the cable covered with an inner shell. At the customer's request, a waterblocking thread or tape can be placed under the corrugated steel armor.

- The central power element

- Optical fiber

- PBT tube

- Hydrophobic gel

- Aramid (ZN) or glass (BN) yarns

- Inner sheath

- Corrugated steel armor

- Outer protective sheath

COLOR IDENTIFICATION OF OPTICAL FIBERS AND TUBES (IES 60304)

1-12 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

Fiber | red | green | dark blue | yellow | white | grey | brown | purple | blue | black | orange | pink |

Tube | red | green | dark blue | yellow | white | grey | brown | purple | blue | black | orange | pink |

At the request of the customer, the color identification of fibers and modules (as well as the sequence of modules assembly by color) can be changed.

The number of optical fibers | 2-24 | 26-48 | 50-72 | 74-96 | 98-144 |

The number of tubes (max.) | 6 | 6 | 6 | 8 | 12 |

The number of optical fibers in the tube (max.) | 4 | 8 | 12 | 12 | 12 |

Operating temperature | -40 °C.....+60 ºC |

Cabling temperature | -10 °C.....+50 ºC |

Storage and transportation temperature | -50 ºC......+50 ºC |

Minimum bending radius | 20xD |

Tensile strength (IEC 60794-1-2) | 1 ÷ 3.5 kN |

Crush strength (IEC 60794-1-2) | 3.0 kN/100 mm (minimum) |